Gypsum is one of the 3 main materials in the field of building materials, and now gypsum mortar plastering has become the mainstream in construction sites. With its good physical and mechanical properties and construction performance, gypsum mortar is widely used in building interior wall plastering projects, it is the best choice for developers, contractors, and construction units. So How to improve the quality of gypsum mortar? Let’s take a look.

1. Raw Materials

In addition to production and formulation, the quality of mortar products is mainly affected by raw materials, the calcined gypsum powder is the primary condition. Reasonable particle size dispersion is the guarantee of mortar quality. The poor quality powder may lead to different problems in construction. For the calcination, cooling, aging, homogenization, grinding, and modification of gypsum powder, a series of measures should be taken, as well as centralized control. Only the quality of gypsum powder is stable, and the quality of gypsum mortar can be guaranteed.

2. Setting Time

The setting time of gypsum mortar is very important. Too short a setting time is not conducive to construction. Too long will cause the strength to weaken, and the surface to chalk or crack. Delaying the setting for too long can cause a weakening of strength, resulting in chalking or cracking of the mortar finish. The setting time of mortar is affected by various factors, including the change of gypsum powder, the temperature of the construction site, the PH value of the product, etc. Therefore, various factors should be considered in the formulation composition, and the difference in setting time between laboratory and field construction should be considered.

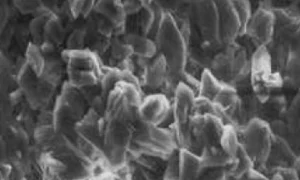

3. The Quality of Gypsum Powder

From MilaCell’s experiment, the hardened crystals of different particles are different. The larger the particle size, the lower the dissolution rate, resulting in reduced saturation. Only suitable grinding time can get good quality gypsum powder. The quality of gypsum powder is very important through experimental comparison, and only good quality gypsum powder can ensure the quality of mortar. Poor quality gypsum powder will weaken the bonding force and the macro strength.

4. Construction Operability